|

The OLYMPUS CIX100 inspection system is a dedicated, turnkey solution for manufactures who maintain the highest quality standards for the cleanliness of manufactured components.

Quickly acquire, process, and document technical cleanliness inspection data to comply with company and international standards. The systemвҖҷs intuitive software guides users through each step of

the process so even novice operators can acquire cleanliness data quickly and easily.

OLYMPUS CIX100 Turnkey Technical Cleanliness Inspection System: Simplify Your Technical Cleanliness

The cleanliness of components and parts is at the center of the manufacturing process. Meeting high standards for counting, analyzing, and classifying the often micron-sized contaminant and

foreign particles is important for all processes: development, manufacturing, production, and quality control of the final product. International and national directives describe the methods and

documentation requirements for determining particle contamination on essential machined parts since these particles directly impact the lifespan of parts and components. Previously,

the mass of residue particles was used to characterize the residue. The standards in use today demand more detailed information about the nature of the contamination such as the number of particles,

particle size distribution, and particle characteristic.

The OLYMPUS CIX100 Cleanliness Inspection System is designed to meet the cleanliness requirements of modern industry and national and international directives.

Standard Process for Cleanliness Inspection: Preparation and Investigation

(01:Extraction, 02:Filtration, 03:Weighing, 04:Inspection, 05:Review, 06:Results)

Simple and Reliable

Seamlessly integrated hardware and software result in a durable, high-throughput system that delivers reliable and accurate data.

- вҖў Easy Setup for True Turnkey Functionality

- вҖў Accurate repeatability and best secure by invariant system setup

- вҖў Excellent optical performance and reproducible imaging conditions

- вҖў Proven durability by reproducible positioning and integrated calibration device

- вҖў Full system integration for high performance

Intuitive Guidance for Maximum Productivity

Dedicated, easy-to-use workflows minimize user action and guarantee reliable data пјҚ independent of the operator and experience level.

- вҖў Step-by-step guidance to improve productivity and reduce inspection and process time

- вҖў User right management to restrict functionality and avoid avoids operator handling errors by restricting functionality

- вҖў Touch screen support for efficient operator handling

- вҖў Compliant One-Click Reporting for direct documentation

- вҖў Data Management by automated results storing and sharing options

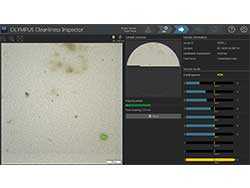

Fast Live Analysis

The unique all-in-one-scan solution enables scans to be completed twice as fast as other inspection systems. Counted and sorted particles are displayed live while powerful, easy-to-use tools make it easy to revise inspection data.

- вҖў Overview image for direct identification of filter coverage, particle clustering or worst particles

- вҖў Automatic live processing and classification of contaminant particles ranging from 2.5 Вөm up to 42 mm

- вҖў High Throughput by unique all-in-one-scan technology for detection of both reflective and non-reflective objects in one scan

- вҖў Live analytics and result display for shortest reaction time

- вҖў Compliant results by support of international standards

Efficient Data Evaluation

Powerful and easy-to-use tools support to revise inspection data. Highest flexibility is guaranteed by support of all international standards. Clear representation of all relevant inspection results in a maximum time saving.

- вҖў Clear arrangement of images and data for efficient data review

- вҖў Visualization of different particle views for immediate identification

- вҖў Proven guarantee as particle location and thumbnails linked with their dimensional images

- вҖў Easy reclassification, review revision and recalculation of inspection data

- вҖў Short reaction time by live display of overall cleanliness code, particle and classification tables

- вҖў Full control by displaying complete inspection data set in one view

Compliant Report Creation

One-click reporting meets the requirements and methodologies set forth in international standards.

- вҖў Completely intuitive and professional documentation based on compliant templates

- вҖў Smart variability by customer adaptable templates

- вҖў Utmost flexibility by support of various output formats

- вҖў Efficient and time-optimized exchange by direct file sharing options

- вҖў Sophisticated data storage options for long-term justification of results

Reliable Turnkey System Solution : Automated and Accurate For High Reproducibility

The OLYMPUS CIX100 system is a turnkey solution designed to meet the needs of automated cleanliness inspection. Each component is optimized for accuracy, reproducibility, repeatability, and seamless integration for reliable data in a high-throughput system. The system is designed for excellent optical performance, reproducible observation conditions, and repeatability. At the same time, this cleanliness inspection system helps minimize human error by automating critical tasks.

- Reproducible Imaging Conditions (Camera Cover)

Highest reproducibility by protected camera alignment to prevent unwanted misalignments.

- Innovative Polarization method (Detection Unit)

Detects both reflective (metallic) and non-reflective particles in a single scan.

- Proven Durability (Stage / Stage inserts)

Accurate and reproducible positioning and an improved focus drive guarantee reproducible positioning. The stage insert maintains a secured membrane position and features an additional insert for the integrated calibration tool.

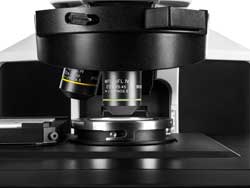

- Excellent Optical Quality (Microscope)

Perfect image quality for analysis by excellent optical components, like Olympus UIS2 objectives and high resolution camera.

- Easy to Use (Software)

Simple and easy-to-use software with intuitive step-by-step workflows leads users through the complete inspection process and helps minimize operator error.

- High Performance (Workstation)

The powerful workstation is equipped with a touch-screen monitor for efficient operation.

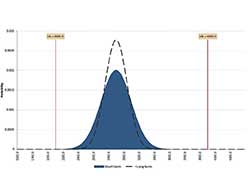

Reproducibility and Repeatability

The diagram illustrates the OLYMPUS CIX100 precision by verify the measurement stability and repeatability using the Process Performance Index (PPk). The same sample at 5X and 10X magnification was measured several times (10 times) and the particle count from typical size classes was extracted. The diagram shows the evaluation of CPk and PPk on class E (50-100 Вөm).

The OLYMPUS CIX100 system is easy to use, so even inexperienced inspectors can acquire accurate and reliable data. Preconfigured hardware and dedicated system solutions help ensure that your settings are correct for accurate and repeatable inspection results.

Excellent Optical Quality

OlympusвҖҷ high-quality UIS2 objectives help ensure the best optical performance for excellent measurement and analysis accuracy. A dedicated light source maintains a consistent color temperature optimized for cleanliness inspection.

Optimized Reproducibility

The integrated calibration slide helps maintain regular system verification.

Reproducibility has been optimized by eliminating moving parts from the illumination light path, maximizing automatic functionality, and creating intuitive workflows that limit potential operator errors. The integrated calibration slide helps maintain regular system verification.

Secure Setup

The optical path alignment, motorized nosepiece, and the camera are protected by a cover to prevent any accidental modifications.

Intuitive Guidance for Maximum Productivity

The clear structured user interface not only makes cleanliness inspection repeatable and reproducible but also easy for experts and non-experts alike.

The OLYMPUS CIX100 system delivers enhanced performance and productivity through the entire inspection process and is designed to make cleanliness inspection easy for inspectors of every experience level. The software provides step-by-step guidance through the complete cleanliness inspection. Intuitive workflows improve productivity and confidence in results while reducing cycle time, cost-per-test, and handling errors. The result is a system optimized to maintain high quality standards.

Easy for everyone

Step-by-step the intuitive interface guides operators of any experience level through the complete investigation process and minimizes inspection and process time for daily use.

OLYMPUS CIX100 redefined the user operation and make cleanliness inspection easy for everyone even by non-experts. Every kind of user produces inspection data they can rely on. The system reduces complicated adjustment by extensive. The intuitive workflow is based on just three steps: Inspect sample, Review results and Create Report. The system reduces complicated adjustment by extensive user guidance leading through all process steps in respect of international standards and by a maximum use of automated functions.

Reliable Data

The system reminds to perform automatic system checks for accurate results on a regular basis; and pre-configured and customized system configurations supports the operator on daily purposes.

The combination of a pre-configured, pre-calibrated system and intuitive user interface helps make cleanliness inspection easy for inspectors of every experience level.

Storage and Sharing

All data is saved automatically. The data management section is where users can access all of the archived samples and their associated data and reports for revision or information distribution.

Management Tools

The OLYMPUS CIX100 system enables administrators to control which users have access to different parts of the system. Depending on an operatorвҖҷs level of experience, the system administrator can define variable roles and choose which functionality to assign to operators. Power users may have access to the complete system setup, while inexperienced users can be limited to basic workflows. This functionality helps ensure that inexperienced users generate reliable results.

User rights allows the administrator to define roles for operators with marked-off functionality

Touch Screen Support

High performance by touch technology

The OLYMPUS CIX100 softwareвҖҷs large buttons are perfect for working with the systemвҖҷs modern and efficient touch-screen technology.

Inspection Configurations

The OLYMPUS CIX100 system is already configured and calibrated when it is delivered but can be easily modified and customized to your applications and requirements.

Inspection configurations are used to specify all of the parameters for sample inspection, including rules for the characterization of particles, setting particle families, and types.

Fast Live Analytics and Review

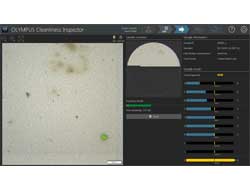

All Relevant Data Displayed in One Place

All relevant data are displayed live on a single screen during the inspection, enabling the operator to stop or interrupt the inspection if a test fails.

The OLYMPUS CIX100 system offers high-performance image acquisition and accurate live analytics of both reflective and non-reflective particles ranging from 2.5 Вөm up to 42 mm in a single scan thanks to an innovative polarization method. This unique all-in-one-scan solution enables scans to be completed twice as fast as other inspection systems. Counted and sorted particles are displayed live and sorted into size classes, supporting direct decision making for reprocessing and helping ensure a fast reaction time in case of a failed test.

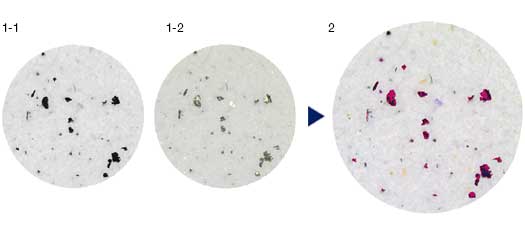

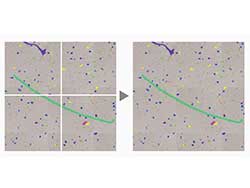

Fast: Capture Data in a Single Scan

An innovative polarization method based on wavelength separation and color detection detects both reflective (metallic) and non-reflective particles in a single scan. Integrated into the microscope frame, this high-throughput design enables scans to be completed twice as fast as other inspection systems and eliminates operator interaction with system components, such as the polarizer, which can negatively impact the system settings, leading to potentially incorrect results. The all-in-one-scan technique increases the number of inspected particles, reducing the cost per test and shortening the reaction time in case of a failed test.

1: вҖҷClassicalвҖҷ method, 2: вҖҷNewвҖҷ method

(1-1:Non-reflecting, 1-2:Reflecting, 2:Combinded)

An innovative polarization method detects both reflective (metallic) and non-reflective particles in a single scan.

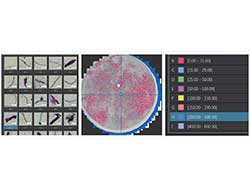

Direct Identification

The overview image assists with evaluating filter coverage, particle clustering, or worst particles, so users can react quickly before the final inspection starts

The sample overview image is created at the beginning of the sample inspection and displays the entire filter at low magnification. The overview image helps to identify filter coverage or particle clusters before the sample inspection starts.

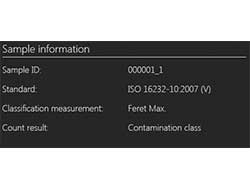

Sample Information Overview

The sample information area lists the most interesting data

Inspection configurations are used to specify all parameters for sample inspection.

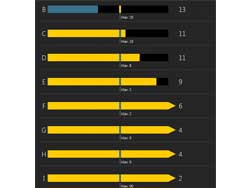

Live Analytics for direct result feedback

Predefined acceptable particle counts per size classes are displayed and the sample can be validated (OK) or rejected (NOK) even before the complete membrane is acquired.

The OLYMPUS CIX100 system counts and sorts particles into the size classes defined in the inspection configuration. Direct result feedback including classification evaluation, enables users to monitor results during acquisition. A statistical control chart function visually illustrates the level of particle class compliance, for improved reliability.

Detect Small and Large Particles

Image stitching automatically reconstructs images of large particles

Live processing and classification of both small and large particles according to international standards (2.5 Вөm up to 42 mm).

Time Information

Clearly view the time remaining for sample acquisition.

Efficient Data Evaluation

All particles and classification tables, overall cleanliness code, particle location, and the standard used appear in one view.

The OLYMPUS CIX100 system includes powerful and easy-to-use tools to revise inspection data with a fast guided particle review. The one-click reclassification function provides users flexibility and supports international standards. Thumbnail images of every contaminant detected by the system are linked together with dimensional measurements, making it easy to review the data. Retrieving a particular contaminantвҖҷs information is simple. Through the review process, all results are updated and displayed automatically in all views and size classification bins. This leads to maximum time savings with clear representations of all relevant inspection results.

Deep Data Insights for Direct Identification

Visualization of different particle view eg. largest reflective or non-reflective particles

Clear arrangement of images, data and results for immediate decision making for reprocessing. At-a-glance display of complete inspection data in various selectable views. Images of particles organized from largest to smallest for all kind of particles (reflective or non-reflective).

Particle Location

When selecting a dedicated thumbnail, its location is automatically shown in the overall image. With just one click, particles can be deleted or reclassified into another particle family.

Proven Guarantee

Visualization of different particle view eg. largest reflective or non-reflective particles

Thumbnail images of all detected contaminants are linked with their dimensional measurements, making reviewing, revising, and recalculating particle data before documenting the results convenient.

Trusted Results

Classification and particle tables list the results according to the selected standard.

Classification and particle tables show the results according to the selected standard and particle data respectively.

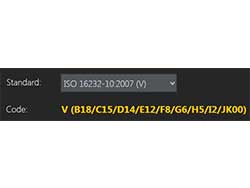

Support Standards

Evaluation is performed according to all major international standards used in the automotive and aerospace industries including:

- ISO 16232-10 (VDA 19.1)

- ISO 4407:1991

- ISO 11218:1993

- ISO 12345:2013

- NAS 1638:1964

- NF E48-651:1986

- NF E 48-655:1989

- SAE AS4059:2011

Companies also have the flexibility to set up their own evaluation standards

Direct Result Feedback

The overall classification results based on the selected standard are calculated and displayed.

Instantaneous calculation and presentation of overall classification contamination class code (CCC) according to the selected standard.

Reclassification

Different Cleanliness Codes

The system supports one-click reclassification of all supported standards. Select the standard and the cleanliness code is displayed.

Quick and Easy: Review, Revise, and Recalculate Inspection data

Operators can easily revise their inspection data. Powerful software tools including delete, split, and merge make revising the data simple.

The OLYMPUS CIX100 system has tools that make it easy to revise inspection data during the review step. (1. Delete, 2.Split, 3.Merge)

Advanced Particle Information

Results of height measurements for selected particle are automatically added to the result sheet for further investigation.

The OLYMPUS CIX100 systemвҖҷs functionality can be enhanced with a height measurement solution consisting of a 20X objective and special software to fulfill the VDA 19 requirements for height measurements. For selected particles, the height measurement is performed either automatically or manually. The calculated height value is listed as an additional data field in the results sheet.

Define company standards

Evaluation is performed according to all major international standards used in the automotive and aerospace industries. Companies also have the flexibility to set up their own evaluation standards.

Efficient Report Creation

Reports that comply with international standards.

The smart and sophisticated reporting tools based on predefined templates that comply with industry standards enable easy one-click digital documentation of the inspection results. The results are created in Microsoft Word 2016 and can also be directly exported as PDF so that data can easily be sent via email. Report templates help inexperienced operators avoid mistakes, but can be easily modified to meet the needs of your company. Tools for data sharing and reporting save time and increase reaction time and productivity. The OLYMPUS CIX100 system can also archive reports and data for record keeping.

Completely Intuitive by Predefined Templates

The smart and sophisticated reporting tools of the OLYMPUS CIX100 system are based on predefined, professional-looking templates. All available templates are clearly listed.

Efficient and Easy

Analytical reports comply with the standard used during analysis.

A list of available templates is displayed based on the standard used during analysis and allows fast creating of compliant reports even by unexperienced operators.

Easy Data Export

The software supports output formats such as MS Word or PDF.

Exporting a report is as easy as clicking your mouse. The operator can choose to export the reports into MS Word or PDF, depending on their requirements and needs.

Long-Term Data Safety

Capability to justify decision after years.

Inspection data and reports need to be achieved for a certain period of time.

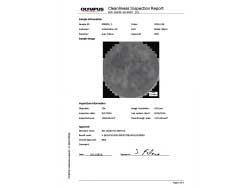

Sample Information Area

The information page of a report

This area of the report consists of information about the sample such as customer, examiner, order number, and date of inspection. All data are inserted automatically.

Classification Table

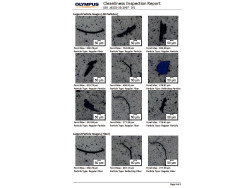

Because the largest particles detected during the scan are of high interest, this report section lists the ten largest particles found during the inspection.

This section of the report incorporates the data calculated during the inspection according to the standard used and displays information such as size class and range information, as well as the absolute numbers of particles detected and the contamination class.

Images of Largest Particles

The result page showing images of the largest particle

Thumbnails of the largest particles are displayed together with the particle parameters and the particle class. Thumbnails also show images of contaminants reconstructed by stitching smaller images together.

Hardware

System environment limitations

Software

Optional Solution CIX-S-HM

Environment law and regulations

|