|

The DSX500i is a high-resolution inverted motorized scope with 13x zoom optics. This scope offers a new level of inverted metallographic microscopy with its operating simplicity and absolute reliability.

к°ңмҡ”

Operating Simplicity that Guides Operators to Optimum Output, Regardless of their Experience

A new way to see. No peering through microscope eyepieces, because everything shows on the GUI screen. So you operate the scope with touch panel, mouse, or computer. What's more, virtually anybody can use this new operating system, whatever their experience. The screens guide the operator through the procedure, from inspection to measurement and analysis to final report. Short, simple steps. Quick results.

Three Modes to Set According to Operator Experience and Job Demands

Select Tutorial Mode or Advanced Mode to match the experience of the operator and the job at hand. And Advanced Mode can be customized to match operator experience or to do routine work. The operator's ID and password open the application, and it automatically sets the scope to the operator's preferred observation, analysis, or measurement settings along with the screen visual the operator normally uses.

|

Tutorial Mode

Eliminates the confusing aspects of operating a microscope. Just follow the suggestions the system gives for excellent output every time. |

|

Advanced Mode

Makes jobs super easy for the experienced operator. Laid out for action. Powered controls make operation much speedier. |

|

Operator Mode

This mode is customizable for speedy routine work. Most efficient when the same task is done repeatedly. |

New User Interface Changes Thinking About Microscope Operation

GUI enables a direct, comfortable operation |

Where an operator had to make complicated adjustments before, with DSX500i, it's simple. Once the sample is in place, everything is controlled by computer mouse, joystick, or touch screen - inspection position, focus, zoom, illumination, and choice of several inspection and operation methods. And you can easily find the inspection position you want, just by moving the image on the touch screen with your finger until it is in the right place. What's more, pinching-

enlarging by spreading two fingers, reducing by bringing two fingers together-work on the DSX500i touch screen as well. All controls are direct and easily performed. Furthermore, auto-focus/auto-gain make sure illumination of and focus on the sample are correct. |

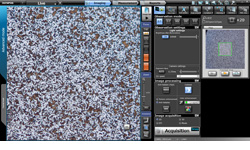

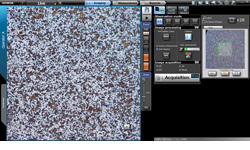

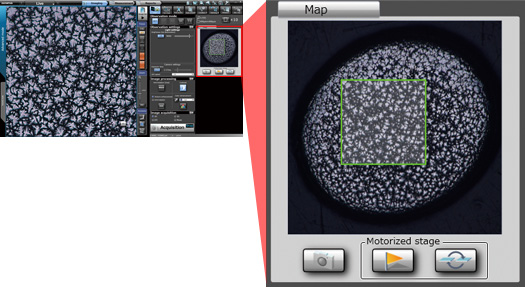

Macro-mapping Means You Never Lose Track of the Place You're Inspecting

Where conventional microscopes tend to lose focus in dark-field image, DSX500i stays in bright-field image mode even when changing observation methods. That means no confusion when increasing or reducing magnification. On the screen, a macro map shows the exact observing point. And the panoramic view function combines photos of several points into a single, larger image.

Macro map always shows where you are |

Optical Zoom Gives Close-Up and Wide-Angle as Needed

Zoom lens changes magnification |

Change magnification as needed, even by slight degrees, with the view automatically in focus by AF function as the change is being made. A single lens gives you optics of 13x and digital zoom for a maximum of 30x. |

Operating Simplicity Lets even the Inexperienced Observe Samples They Couldn't Before

The leading-edge digital technology of this microscope lets you see more than any other microscope can. Heretofore, only experts with years of experience could adjust microscopes to achieve really good views of relevant samples. But DSX500i allows any operator to do that with a GUI screen. Now all it takes is a touch of the finger to follow a few easy steps to get exact output from inspection to diagnosis to pertinent reports.

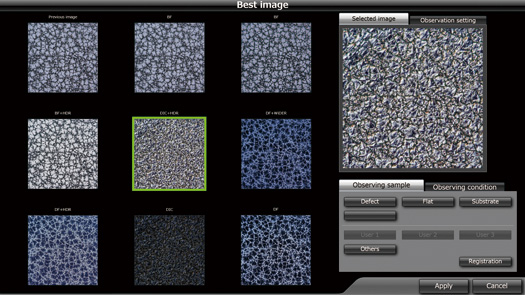

Best Image Function Ensures Optimum Microscope Performance

Now you can operate your microscope just by choosing, and leave the inspection method up to the microscope. That ensures the best possible image, whether looking for defects, uneven surfaces, or foreign objects. Anyone can operate the system, beginner or expert, and it can be customized for operator or operation. Put the inspection methods in memory, and whoever operates the scope will get the same results; no scattering.

Best Image - Just choose the image you want from the previews on the screen

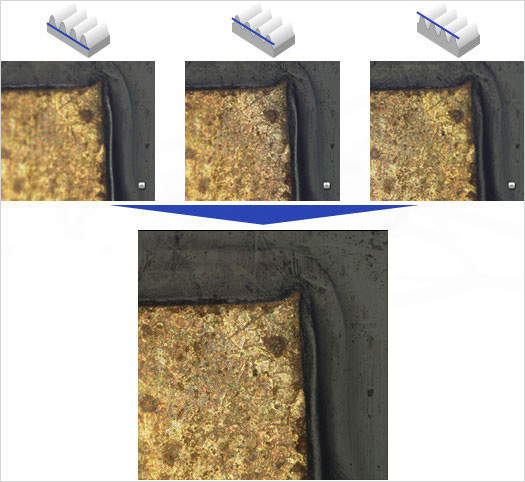

HDR Gives Ultra High-Definition Visuals that Go Beyond the Human Eye

Dark-field risks blackout and bright-field risks halation, but the HDR (High Dynamic Range) function of DSX500i scopes synthesizes several images taken at different exposures to eliminate such problems. HDR promises high-fidelity images in which textures stand out and there is no halation, so defects that were undetectable now stand out.

HDR - enables ultra high-definition inspection in dark-field and DIC images with one click

WiDER Provides Easy Inspection of Samples with High Luminance Difference

If the shadowed areas black out, merely upping the illumination power is often not enough, because then halation occurs. Olympus intelligent image processing technology eliminates these problems with WiDER, a proprietary system ready to go at the click of a button. It takes care of the high contrast problems without reducing the frame rate. No blackouts. No halation.

Change Observation Methods with One Click - No Presetting Necessary

A click of a button gives you the image you want on screen |

With virtually every industrial observation method at hand, it's easy to choose the proper one for the current task. Just choose the proper method with the click of a button. No complicated adjustments needed. |

Various Observation Methods with Simple Operations.

Quickly Achieve the Image Definition You Need for Observation

Can be used for any inverted metallographic microscopic observation method. Also, DSX500 Series scopes offer a new MIX observation method that combines BF and DF to detect even the tiniest defects and imperfections. And advanced optics ensure the high-definition images basic to observation and measurement. The DSX Series also offer a Multi-preview function that allows touch-screen selection of observation methods.

BF BF

Bright-field observation. The most common method with optical microscopes.

|

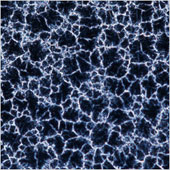

DF DF

Dark-field observation. Illuminate from the side to emphasize imperfections. Best method for identifying defects.

|

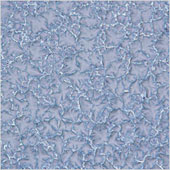

DIC DIC

Differential Interference Contrast observation. The method to use when inspecting uneven surfaces.

|

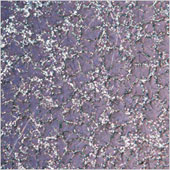

PO PO

Polarized Light Observation. With metal crystals, etc., the polarization characteristics result in a change of color.

|

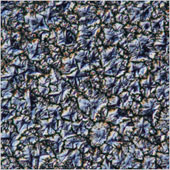

MIX (BF+DF) MIX (BF+DF)

Use bright-field (BF) and dark-field (DF) observation methods at the same time, a mix of BF ease of observation and DF ease of detection.

|

|

A Simple Operation Lets You See Now What You Couldn't See Before

The DSX500i requires no extensive knowledge or special techniques to show you exactly what you want to see. By calling on leading-edge electronic technology, you can now see what was unclear or impossible before. Of course, there are no difficult processes either. Just press the buttons on the menu to see what you want.

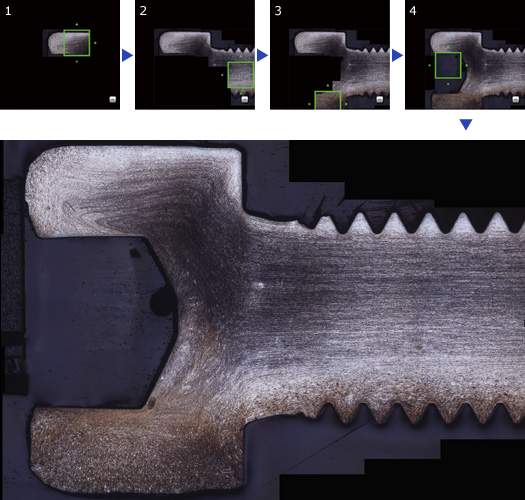

Panoramic Photos Include Areas beyond the Field of Vision

No such thing as "outside the field of vision." Just move the observation position on the screen, and the motorized stage will move the sample to that place. As the stage moves, the system automatically stitches images into a single large field of view, in real time. Where conventional microscopes reduce field area with increases in magnification, Panoramic View maintains the original field while giving close-up clarity - with 2D, expanded focus, or 3D, or any combination of one or

all.

Panoramic photos - With a bolt cross-section for example, use the mouse or your finger to select what you wantгҖҖin the view, and it's all linked together on screen

Makes Your Routine Work More Efficient

You can set the image movement (up, down, left, right, slanted, etc.), the display position and method, and the sample stage will automatically obey those settings as it starts to work. This significantly shortens the takt time when observing or measuring the same kind of samples one after another.

Every Part of Samples with Uneven Surfaces is in Focus with EFI (Extend Focal Image)

For example, even the most carefully polished sample may show unevenness where different materials meet. With conventional scopes at high magnification, such unevenness is out of focus and indistinct. DSX Series scopes move the focus to the higher portion of the sample and synthesize an image of the entire field that is perfectly in focus.

гҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖEFI image

Color Enhancement Feature Shows Only What You Want to See

If you put what you need to see in color and leave the rest in monotone, it's much easier to find defects, if any exist. And you can photograph just that part, too, which makes reports even more effective.

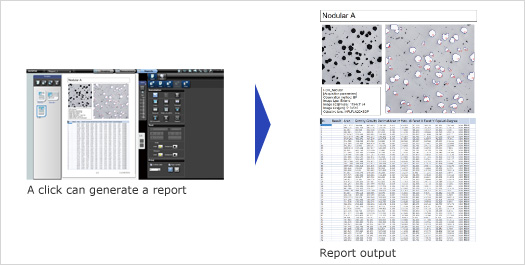

The Report Function Gathers the Results Together Efficiently

With DSX500i, you can do observation or measurement, and the operator's workflow includes preparation of relevant reports that can be output in rich text (rtf), or PDF formats.

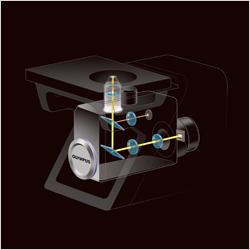

DNA from Olympus Gives DSX Microscopes the Ability to See What Digital Microscope Cannot

Olympus guarantees the reliability of all DSX500i microscopes because they are born of Olympus optics and opto-digital technology. Halation is minimal and color reproduction is real. And to make sure of that, Olympus uses the perfect combination of CCD chips and graphic boards. The sample is reproduced with such accuracy it's like a new dimension.

Ultra High-Quality Optics Let You See Into Another Dimension

The optics technology and dedicated lenses - complete with Olympus DNA |

Olympus DNA includes superior engineering and design capabilities as well as proven manufacturing quality. In the clear images produced by the DSX500i opto-digital microscope, you'll find neither flare nor distortion. That's something no digital microscope can claim. |

Dedicated DSX500i Field Lenses Make High-Grade Image Dissection a Simple Matter

The optics technology and dedicated lenses - Complete with Olympus DNA |

These new lenses (10x, 40x) were especially designed for DSX500i scopes. And they put high NA and low-magnification wide-field observations together, enabling efficient observation and measurement over a broad range of situations. What's more, you can use UIS2 lenses, which provide high resolution and contrast. |

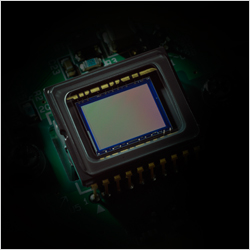

18MP Images Reproduced in very High Resolution with High-Performance CCD*

High-performance CCD |

As the engine that shows exactly what the high-quality optics reveal, exceptionally high-performance CCD reproduces the colors precisely. The image shift function ensures very high fidelity with fine detail processing of images, so the detail clarity extends from corner to corner.

*4800x3600 pixels, 3CCD mode conversion triples the pixel count |

LED Illumination Gives Picture-Perfect Inspection with Much Less Energy

New LED illumination not only assures accurate observation, but also achieves both energy conservation and lower running costs. What's more, the light color temperature does not change with intensity. And the long working life of the elements means the scopes are virtually maintenance free.

Precision Measurement with Absolute Reliability that Cannot Be Matched by Conventional Digital Microscopes

DSX500i scopes show Olympus' dedication to accurate measurement with its telecentric optics and frame design. The measurement capabilities are far and away more accurate than digital microscopes, with much greater reliability. The measurements are true and consistently repeatable, the test for reliable accuracy, always.

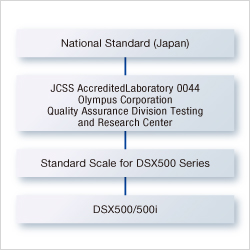

Accuracy and Repeatability Guaranteed

A traceability diagram from a DSX500 series opto-digital microscope |

The DSX500i provide precise and repeatable measurements. Everything from an objective lens to the frame is manufactured in an Olympus factory under strict inspection criteria. The accuracy is guaranteed under the traceability system connecting to national standard.

*Calibration by Olympus or dealer specialists necessary |

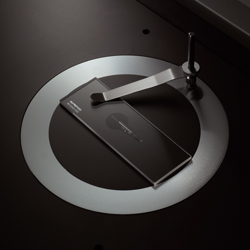

Auto-Calibration Eliminates Setup Scatter

|

Proper calibration is basic to precise measurement, and with Olympus DSX500i, any operator can calibrate simply and accurately. This eliminates scattering that naturally comes when different operators calibrate, and naturally increases reliability of readouts. In addition, the system's calibration report shows who did the calibration and when.

*A special calibration sample is necessary |

Various 2D Measuring Items

Any DSX500i microscope comes equipped for 2D measuring items that are required for an inverted metallographic microscope. And the result of inspection and measurement can be reported by the same application software.

|

Basic measurements includes distance between two points, polygonal curve, perpendicular, distance between centers of circles, angle, area of a circle, free hand |

|

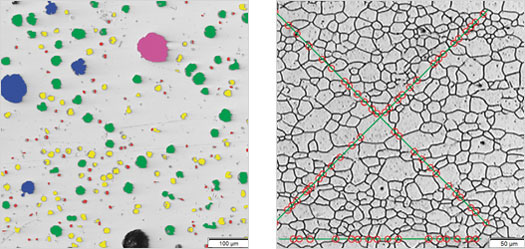

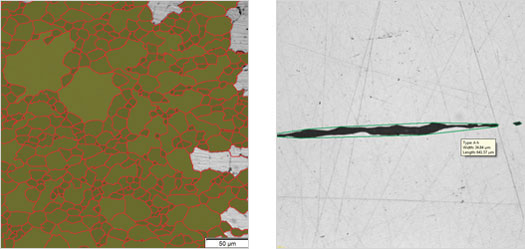

Analysis functions include particle analysis, flat measurement, and caliper measurement A wide-range of measurement items - enable measurement from every side for various applications |

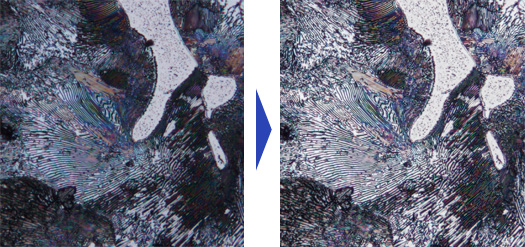

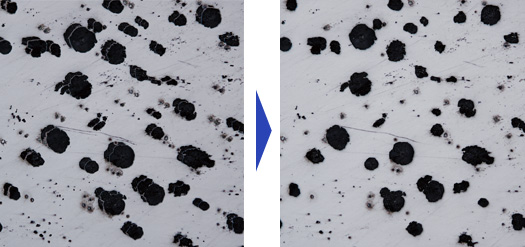

Vibration Compensation Perfects the Observation/Measurement Environment

The frames absorb any vibration that might affect inspection or measurement at high magnification, and they adjust for any vibration-caused blur. This software technology ensures accurate measurement at any time.

Without compensationгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖWith compensation

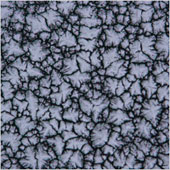

OLYMPUS Stream Can Analyze DSX500's Data

Granularity analysis, cast iron analysis, non-ferrous metal inclusions analysis, chart comparisons-virtually every analysis necessary in metallographic evaluation can be done with OLYMPUS Stream, an image-processing program. It accesses all data in the DSX500 data files, including basic calibration data, and offers a diverse and flexible work flow that moves from measurement to analysis to report production.

Cast iron analysisгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖGrain sizing intercept

Grain sizing intercept гҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖгҖҖNon-metallic inclusion analysis

мӮ¬м–‘

| DSX500i Specifications |

Main frame

|

Zoom ratio |

13.5x optical zoom (0.26X-3.5X), 30x with digital zoom |

| Mountable objective lens |

DSX dedicated objective lens |

XLMPLFLN10X,XLMPLFLN40X |

| UIS2 objective lens |

MPLFLN1.25X,MPLFLN2.5X,MPLFLN5XBDP,MPLFLN10XBDP,MPLFLN20XBDP,

MPLFLN50XBDP,LMPLFLN10XBD,LMPLFLN20X,LMPLFLN50X,MPLAPON50X |

| Illumination |

Embedded standard |

Bright field: LED, Dark field: LED |

| Optional illumination |

High intensity LED*1 |

| Camera |

Image sensor |

1/1.8 inch, 2.01 megapixels, Color CCD ( Total pixels : 2.10 megapixels)

Total pixels : 1688(H) x 1248(V)

Available pixels : 1628(H) x 1236(V)

Effective pixels : 1600(H) x 1200(V) |

| Cooling method |

Peltier cooling |

| Scan mode |

Progressive scan |

| Frame rate |

15fps / 27fps with binning mode |

| Image size |

Normal : 1194Г—1194(1:1)/1592Г—1194(4:3)

Fine : 1194Г—1194(1:1)/1592Г—1194(4:3)

Super fine : 3594Г—3594(1:1)/4792Г—3594(4:3) |

| Sensitivity |

ISO100 / 200 / 400 / 800 / 1600 equivalent |

| Focusing unit |

Stroke |

35mm |

| Resolution |

0.01Ојm |

| DSX-IFSSU (Motorized) |

Stroke |

50Г—50mm*2 |

| Load capacity |

1kg |

| Stage |

GX-SFR (Manual) |

Stroke |

50x50mm |

| Load capacity |

1kg |

| LCD monitor |

Size |

23" with Touch panel and Full HD color LCD monitor |

| Resolution |

1920(H)Г—1080(V) |

| Weight |

Approx. 38.6kg(Main frame, Motorized stage, LCD Monitor, Control box, PC) *2 |

| Input rating |

100-120V/220-240V, 185VA, 50/60Hz*2 |

|